Safety Key, Feature Symbols and Technology

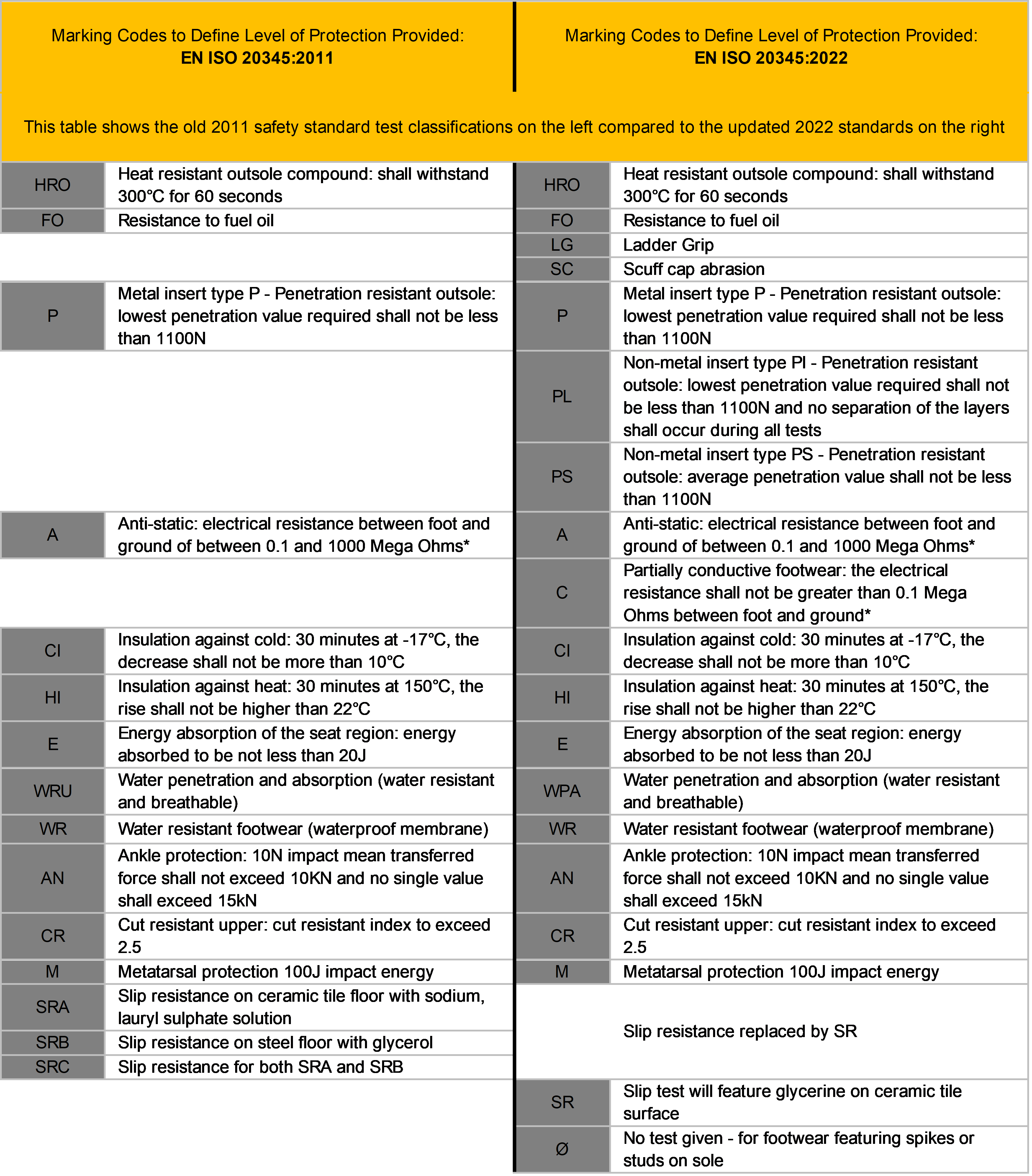

UKCA / CE Standards Coding Changes

The New Standards for Safety Footwear Explained

Reason for changes

The changes proposed are driven by the need for the safety testing to mirror real life working scenarios while making some tests more precise. Developments in footwear materials since the last standard also required attention.

Some aspects of EN 20345:2011 will remain unchanged including their appropriate safety codes.

What are the Key Changes?

Slip Resistance

Under the new standards, SRA, SRB and SRC will disappear. Linked to Health and Safety statistics which highlight slips as the dominant insurance claim for industrial work, slip resistance has become a mandatory test with a minimum standard to meet. This is no code for this minimum slip performance. If the minimum slip performance cannot be met, this must be disclosed.

There is an additional higher standard of slip resistance which can be tested for but this is not mandatory. This new safety code is SR.

Slip Testing will no longer feature a steel surface. Instead, both mandatory and additional slip testing is being carried out on a ceramic tile surface. However, the contaminant solution will change:

- the mandatory test will use sodium lauryl sulphate for its lubricant

- the optional enhanced SR test will use glycerine for its lubricant

The final change to the slip resistance standard is the area of the footwear tested. To mirror real life movement, the heel and forepart are the areas of focus and no longer the flat of the footwear.

The new SR threshold is exceptionally high and will separate premium and lower price point product.

Anti-Penetration Midsoles

Due to the continued growing consumer demand for non-metallic specification the standards have considered the variation in quality of non-metallic midsole offering.

Accordingly, for non-metallic midsoles only, two new tests apply which, in part, attempts to differentiate the quality by which the thickness of a testing ‘nail’ can penetrate the material.

The first test covers more general safety working risks. The testing nail for the new test code PL uses a 4.5 millimetre ‘nail’. In simple terms think of L = Large.

The second new test code, PS (think S = Small) uses a test where there is a greater perforation risk associated - for example factory floors where fine sharp shrapnel pieces may be discarded. The test nail here is smaller in diameter at 3 millimetres.

For metallic midsoles there is no change in testing or standard level currently applied ISO 20345: 2011. The P code will be used for metal midsoles.

Brands cannot not show PL and PS for the same product.

Anti-Scuff Toe Protection

During the product development for BLITZ (2019), Buckbootz worked with the testing body to develop a unique test to help evaluate the durability and abrasion performance of the new lightweight scuff toe component.

In the new standard, the testing essentially follows our approach above by subjecting the scuff toe protection to 8,000 abrasion cycles. On achievement of this standard the product can add SC to the safety specification. In simple terms the testing should not present a hole through the full component on abrasion cycling.

Ladder Grip Test

Linked to the Heath and Safety statistics mentioned earlier the standard has attempted to cover risk associated from working at height particularly working on ladders. The change here covers the waist area of the outsole, its angle, the cleat design and heel breast dimensions.

The code LG will be added to the product specification should the sole meet the new Ladder Grip Standard.

New Water Resistance Symbols

The old symbol of WRU (Water Resistant Upper) has been replaced by a new code WPA (Water Penetration and Absorption). The test has not changed much other than change in dimensions of positioning of the boot and absorption paper used. It is important to note the standard is still evaluating breathability, an important aspect for consumers.

In addition, the WR symbol will be used. This stands for water resistance footwear. In simple terms this is different from WPA above where there is a waterproof booty/membrane/lining used inside the boot.

Ankle Protection

There is a minor update with regards the dimensions of the ankle area for testing. Importantly Buckbootz continues to drive ahead of the market and standards by certifying protection and support for both outer and inner ankle areas.

The new standard makes inner ankle protection (AN) optional.

New Safety Codes

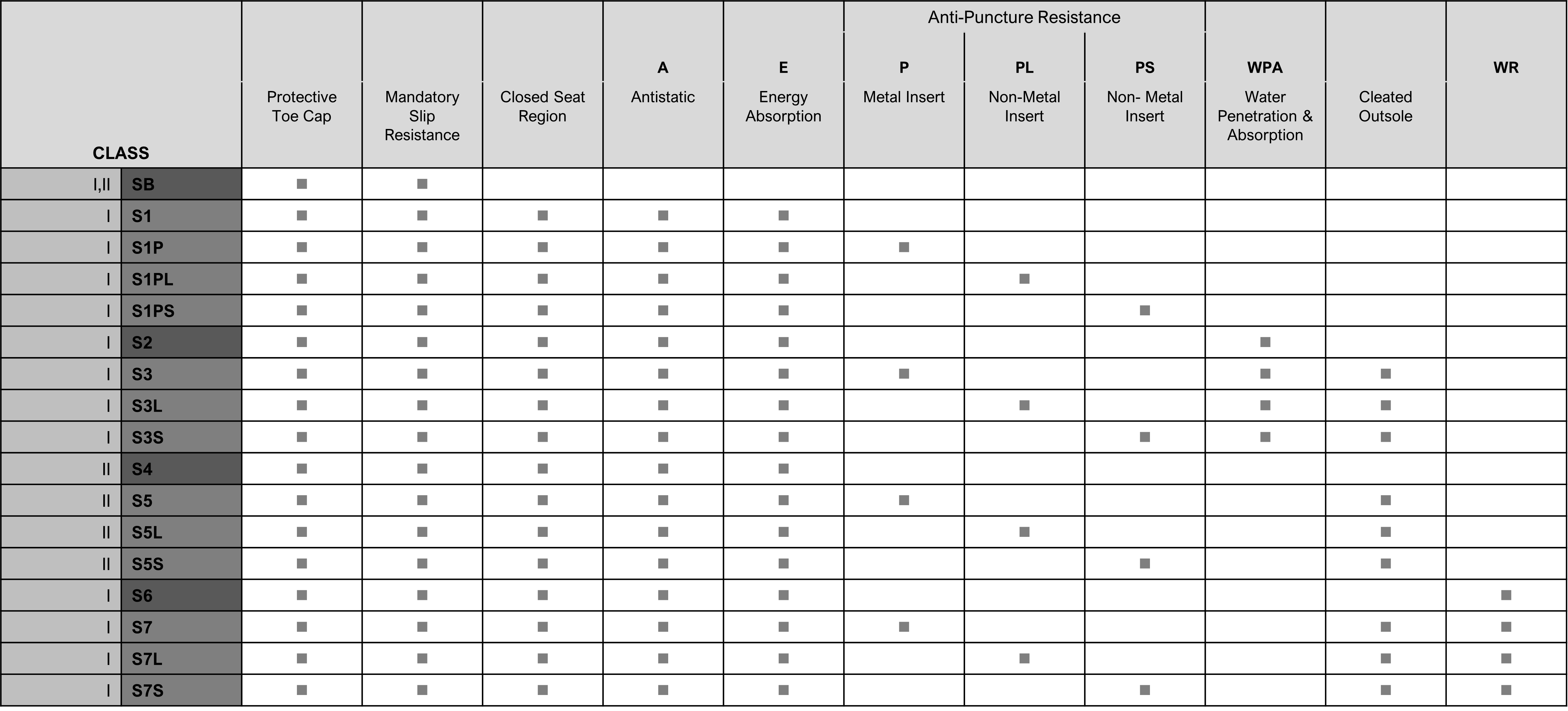

SB P, S1, S3 and S5 safety codes will continue but the main change will be the introduction of a new code S7.

In simple terms S7 would represent the old S3 standard for leather and/or textile uppers but with waterproof specification i.e. WR = water resistance of whole footwear.

Marking Codes

Marking Codes to Define Level of Protection Provided: EN ISO 20345:2022

Class I: Footwear made from leather and other materials

Class II: All entirely moulded footwear

SBH: HYBRID FOOTWEAR that cannot be classified as class I or ll

SB Safety toe cap protection only, tested with 200J impact and 15KN compression force

S1 Class I + Closed heel area + SB + A + E

S2 As S1 + WPA

S3 (metal insert type P) as S2 + P + Cleated Outsoles

S3L (non-metal insert type PL) as S2 + PL + Cleated Outsole

S3S (non-metal insert type PS) as S2 + PS + Cleated Outsole

S4 Upper material of all Rubber or Polymeric as SB + Closed heel area + A + E

S5 (metal insert type P) as S4 + P + Cleated Outsole

S5L (non-metal insert type PL) as S4 + PL + Cleated Outsole

S5S (non-metal insert type PS) as S4 + PS + Cleated Outsole

S6 As S2 + WR

S7 (metal insert type P) as S3 + WR

S7L (non-metal insert type PL) as S3 + WR

S7S (non-metal insert type PS) as S3 + WR

Example of coding changes

NKZ101 current = S3 HRO SRC

NKZ101 New = S3S SC LG FO HRO WPA

DEALERZ Safety current = S3 HRO SRC WR

DEALERZ Safety New = S7S LG FO HRO WR*

BVIZ2 Current = S3 HRO SRC WR

BVIZ 2 New = S7S SC LG FO HRO WR*

B1180 New = SB PS SR LG FO HRO WR*

BVIZ 5 & BVIZ 6 New = S7S SC LG AN FG HRO WR*

*also technically include WPA

For ease, we've summarised these new codes in the table below

Technology

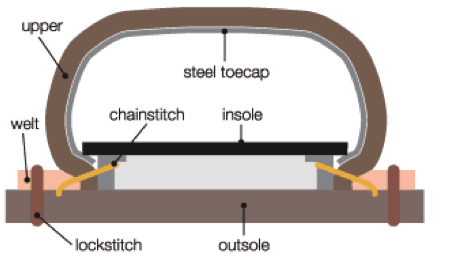

Goodyear Welted

Using a Goodyear Welted construction has a number of advantages. This construction is an extremely robust method of manufacture where a lockstitch sewn welt secures the upper to the inner sole.

Using a Goodyear Welted construction has a number of advantages. This construction is an extremely robust method of manufacture where a lockstitch sewn welt secures the upper to the inner sole.

- The upper is carefully pulled over a wooden last to remove all stretch from the leather. Many vulcanised boots are not lasted. Lasting gives a better fit over the life of the boot.

- Goodyear Welt innersoles are built into the boot, not slipped in afterwards.

- Goodyear Welted boots have a natural cushion filler between the inner sole and outsole. This means greater comfort and fewer aches if you are on your feet a lot.

- Goodyear Welted boots are built like quality dress shoes, allowing your feet to breathe.

- Goodyear Welted boots can be re-soled.

We use this tough construction for the following Buckbootz styles:

Injection Moulded Construction

Injection Moulding, whilst a different construction technique to Goodyear Welted, keeps our footwear light yet extremely durable. Injection Moulded footwear is constructed using advanced rubber and PU injection, mould and clamping technology.

Our Buckshot range is Injection Moulded.

Leather Lined – ‘No Sweat’

When you want breathability as well as safety, you need a leather lined boot from Buckbootz. We use only real cowhide linings, offering natural comfort and a cool feel that man-made linings just can’t match. In fact, our leather linings exceed the European Water Vapour Permeability Test by a factor of three.

Full cowhide lined boots are available on the B425 safety lace boot and B1300 non-safety dealer boot.

Buckflex

The No.1 Dealer Boot range now comes with a built in shoe horn for easy on/easy off, no heel ‘dig’ when driving/operating foot controls plus it helps keep full ankle support and close comfort fit for the lifetime of the boots.

The No.1 Dealer Boot range now comes with a built in shoe horn for easy on/easy off, no heel ‘dig’ when driving/operating foot controls plus it helps keep full ankle support and close comfort fit for the lifetime of the boots.

We use 'Buckflex' in all of our safety dealer boot styles:

Plus it’s a key feature on our non-safety dealer boot styles too:

Cambrelle®

Cambrelle® is used across a number of Buckbootz styles.

Cambrelle® linings help keep feet cooler in summer and warmer in winter. It breathes, letting air in and moisture out. The lining works like a blotter, absorbing foot perspiration. It dries quickly, resists foot odour and mildew. It has the added benefit of being soft and cushion-like for added comfort yet durable and long wearing.

Neoprene®

Neoprene® is used for our Buckbootz Safety Wellington range and our non-safety Buckbootz.

Neoprene® resists degradation from sun, ozone and weather. It provides waterproofing, weight saving, insulation and is flexible. It has chemical, abrasion and oil resistance.